1

/

of

10

Offset Winch Snatch Ring

Offset Winch Snatch Ring

Regular price

$169.99

Regular price

$180.00

Sale price

$169.99

Unit price

/

per

Shipping calculated at checkout.

What the experts have to say

Order Quantity 1 = 1 Ring

For use with synthetic HMPE winch line ONLY

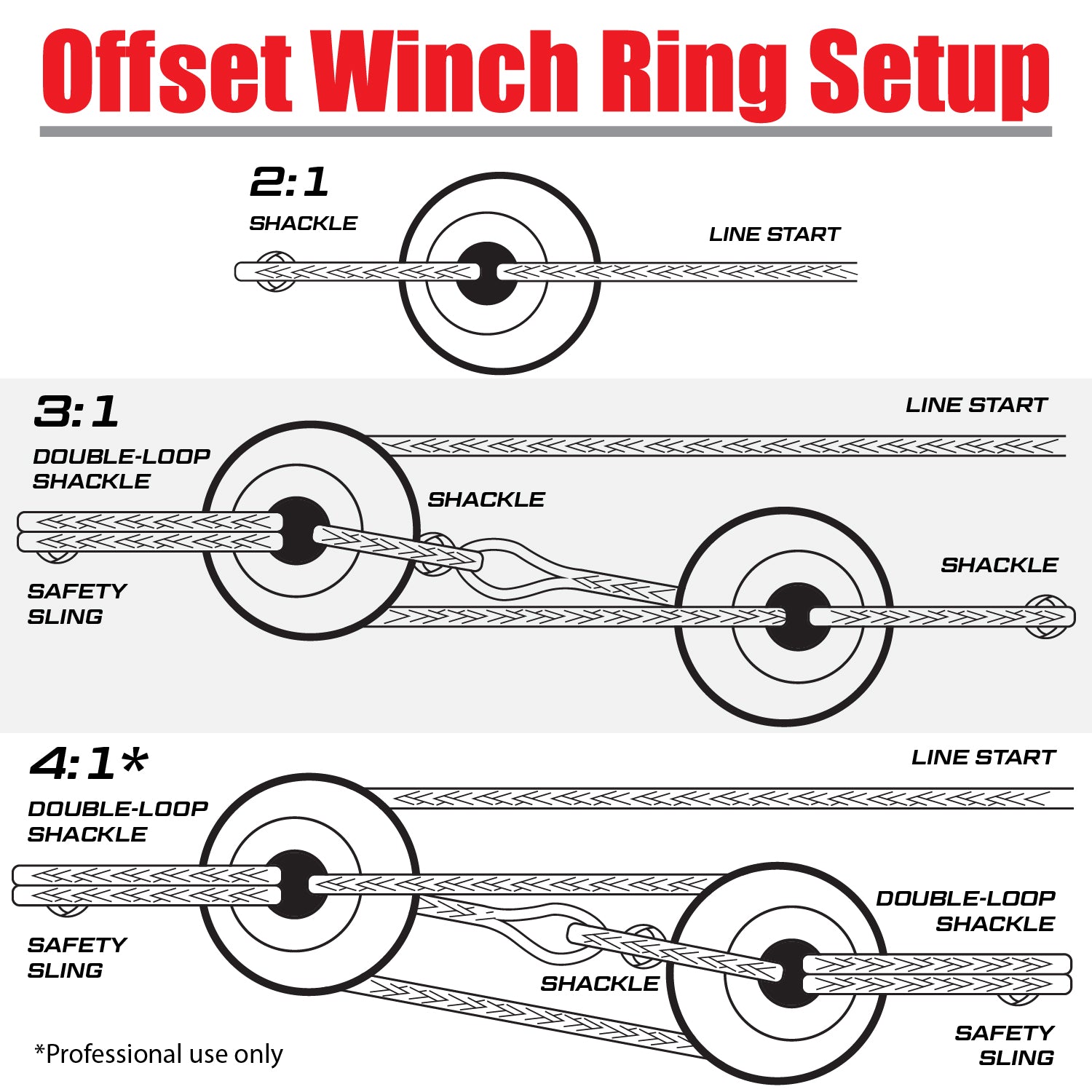

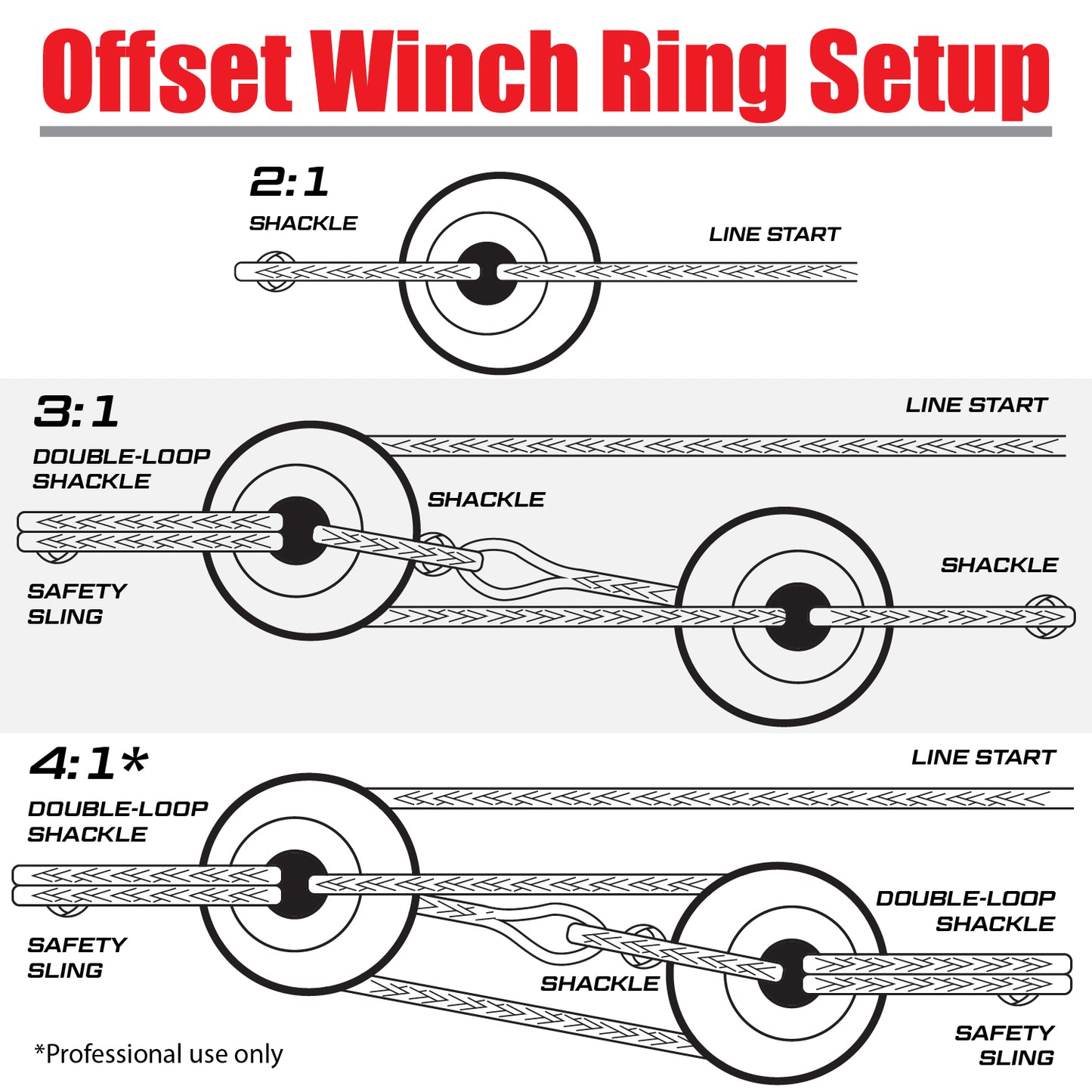

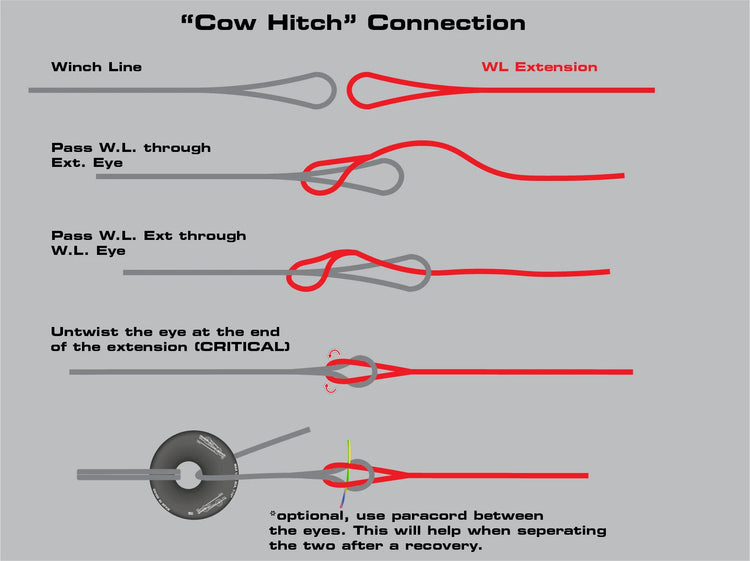

WARNING: When performing a winch recovery, start with a single line pull (1:1), and work up to other configurations, ie 2:1 ---> 3:1, etc. The risk of overloading your tow/connection points increases with each additional configuration. Never exceed a 5:1 pull with this ring.

A 4:1 pull should ONLY be done by professionals, using 2 winch rings, a safety catch sling, and double loop 7/16" soft shackles are required. In these configurations, it is easy to exceed the rating of some tow/connection points, you MUST KNOW those ratings before use.

These are NOT designed for heavy-duty wrecker use. Use ONLY electric bumper-mounted winches rated at 12k lb or less. NEVER use Steel Cable with this ring, Only use a Synthetic (HMPE) winch line no larger than 7/16" diameter. Not for over-head use.

Description

Weighing in at 2.2 lbs you can now reduce your total weight in your recovery gear kit SIGNIFICANTLY. Two of these rings (and three soft shackles{2 double loops and 1 single loop}) can do the job of 4 standard snatch blocks and 5 hard shackles! That is a huge reduction in total weight and gives you a massive increase in configuration options! Gone are the days of worrying about corrosion or bearing maintenance after a messy and wet recovery.

High-quality HMPE winch line can handle operating temperatures of 190°-212° Fahrenheit (100°C) and typically begin to melt around 300° Fahrenheit (144°C) over an extended period of exposure. The Off-set Winch Ring operates in temperature bands less than that of allowable maximum HMPE operating temperatures ensuring your winch line is as happy as can be. Current parasitic friction loss while pulling at peak loads is estimated to be around 10% depending on the quality of the winch line line coating.

Specifications

SPECIFICATIONS

- Type III Hard Anodized Finish in Gun Metal Gray.

- USA Kiser billet 6061 Aircraft Aluminum.

- Machined in Idaho.

- Anodized in Idaho.

- 2.2 lbs

- 5" total diameter.

- 3 1/4" groove diameter (8x 3/8" winch line radius transit+).

- 2-1/4" hole radius. (6x 3/8" winch line radius transit).

- Current "pull apart" MBS 79,590 lbs+

Patent Pending

Shipping

SHIPPING

- We pay for shipping on orders over $200!! US Standard rates only

- Expedited & International shipping services are available for an additional cost at checkout

- Orders ship within 3-5 business days

- Local pickup available at YR Headquarters, ready in 1 hour during normal business hours

Share

Reviews

HUGE BENEFITS

- Cut the equipment you carry in half, reducing weight, saving space

- Reduces line load and strain on winch

- Up to a 4 part line with only two winch rings

- No friction build up on the shackle from a spinning ring

- Reduce line speed

NO BABYSITTING

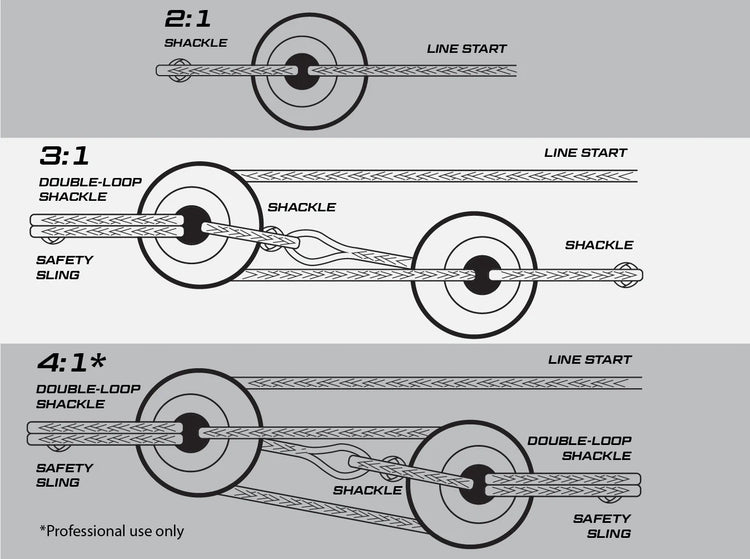

A traditional winch ring requires someone to babysit the winch line, making sure it doesn't fall out of the groove while the line is slack. Also, if you have ever winched while climbing rocks, the vehicle can lurch forward, causing the line to drop out of the groove, then the vehicle can slip back down, causing the full tention to be placed on the soft shackle. Needless to say, it needed a solution for this. With the offset winch ring, on a 2:1 set up, you can dive through the hole instead of the groove, now the line will never fall out.

Innovation

We designed the offset winch ring as the first to allow an extension to pass through the ring, whether it be through the hole or around the groove. You can now park farther away from the stuck vehicle and reduce the amount of times you have to stop and redo the rigging. Simply connect two winchlines by using the "cow hitch" shown in the image.

Ingredients

From birth to finished product, the manufacturing process covers less than 150 miles.

- Designed AND Machined in Idaho

- 6061 Aircraft Aluminum

- Type III Anodizing - Toughest available

- Laser engraved