How Yankum Ropes Makes Matt's Recovery Rope

Share

Hey everybody, I want to show you how we take the highest grade fiber and turn it into the best American-made kinetic recovery rope on the market—Matt's Recovery Rope.

It’s All About The Nylon Core

As I said, it starts with using nylon fiber. We take it into this machine, and we put a very specific amount of twist into the yarn that goes into each one of these kinetic ropes.

Once we have that yarn, we can start the process of making Matt's recovery rope. We take the yarn, we put it on the braider bobbins, and those braider bobbins then go into our braiding machines.

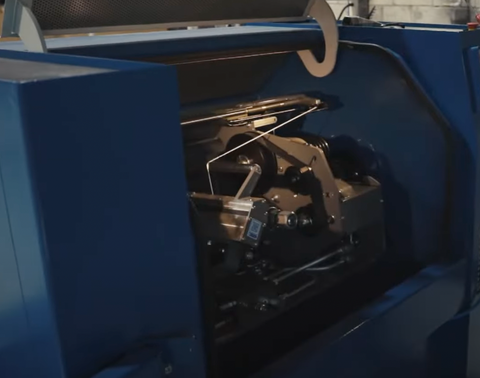

These braiding machines are calibrated to a very specific amount of twist and revolution to then be able to make a rope inside of a rope. This is the first rope; this is our core braiding machine.

Braided Core + Braided Jacket = One Strong Rope

The core braiding machine takes 24 strands and weaves them together to make a very strong standalone rope. This is only half of the rope. This rope is going to be fed into our jacket braiding machine.

With the jacket braiding machine, what it's doing is braiding a rope on top of the core. In our ropes, in the Yankum kinetic rope, half of the load is carried in the core, and half the load is carried in the jacket. That's what makes our kinetic ropes so strong.

Making the Slings

After we get the rope, we have to turn it into slings.

We take the long sections and cut them into shorter lengths, both 20 footers and 30 footers, and then we tie the eyes into each end. We also make our own soft shackles. The soft shackles are the best application for using a kinetic rope when attaching it to other vehicles that are stuck.

Dipped for Durability

Each one of these packages is very carefully inspected through several stages of quality control. The first one is, as we said when we were making the slings, the second one is when we start to dip the rope. The dipping process starts with the eyes. What we do is put a two-part epoxy over each one of the eyes.

What that does is make it a lot more durable and can handle any of the different applications that you might find yourself in. Then we dip every rope in a containment coating.

What this does is glue all of those fine little fibers together so they won't fray when you're out in the wild.

Quality You Can Trust

The final step is the last part of our quality control. After everything's dry, we go through and inspect every rope, and then we tag it and send it out to the customer.

Every one of our recovery ropes is handmade. It’s our mission to deliver our customers American-made kinetic ropes of the highest quality and strength possible, so every part of the process is very carefully inspected, giving you confidence and peace of mind when you need it most.